Balanced Scorecard Measurement + Control Charting Theory

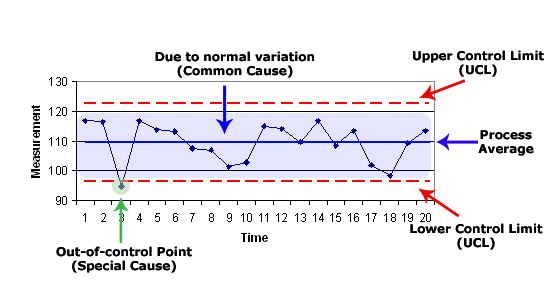

Control charts have long been used in manufacturing, stock trading algorithms, and in other process improvement methodologies like Six Sigma and Total Quality Management (TQM). The purpose of a control chart is to set upper and lower bounds of acceptable performance given normal variation. In other words, the control chart serves to "sound the alarm" when a process shifts (like a machine suddenly breaking on a factory floor) or if someone has a good breakthrough that needs to be documented and standardized across the larger organization. Here is an illustration: (citation)  The Balanced Scorecard system typically uses a baseline, regular measurement and tracking against a target. Actual control charts might not be ideal for your Scorecard, however, the theory is still valuable

The Balanced Scorecard system typically uses a baseline, regular measurement and tracking against a target. Actual control charts might not be ideal for your Scorecard, however, the theory is still valuable

June 2021

| S | M | T | W | T | F | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 |

Monthly Archive

June 2014 (1)

May 2014 (2)

March 2014 (1)

February 2014 (2)

January 2014 (1)

December 2013 (1)

October 2013 (2)

September 2013 (1)

July 2013 (2)

June 2013 (2)

April 2013 (1)

March 2013 (3)

February 2013 (4)

January 2013 (7)

December 2012 (4)

November 2012 (8)

October 2012 (9)

September 2012 (5)

August 2012 (6)

July 2012 (5)

June 2012 (7)

May 2012 (8)

April 2012 (5)

March 2012 (5)

February 2012 (6)

January 2012 (6)

December 2011 (7)

November 2011 (9)

October 2011 (9)

September 2011 (2)

August 2011 (8)

July 2011 (6)

June 2011 (8)

May 2011 (12)

April 2011 (5)

March 2011 (1)

February 2011 (2)

January 2011 (4)

December 2010 (6)

November 2010 (3)

October 2010 (5)

September 2010 (4)

August 2010 (3)

July 2010 (2)

June 2010 (1)

May 2010 (2)

April 2010 (1)

March 2010 (3)

January 2010 (4)

December 2009 (1)

November 2009 (1)

October 2009 (1)

September 2009 (3)

August 2009 (2)

July 2009 (3)

June 2009 (3)

May 2009 (6)

April 2009 (5)

March 2009 (3)

February 2009 (2)

January 2009 (2)

December 2008 (2)

November 2008 (2)

October 2008 (4)

September 2008 (6)

August 2008 (5)

July 2008 (4)

June 2008 (9)

May 2008 (5)

April 2008 (6)

March 2008 (8)